BEIDE 1MT0013 Series Three-phase Asynchronous Motor

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean |

| Port: | Shanghai |

Select Language

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean |

| Port: | Shanghai |

Brand: Beide

Application:: chemical and petrochemical industries, etc.

Rated Power:: 0.55 ~ 90 kW

Frame Size: 80 ~ 280

Voltage And Frequency:: Supports multiple voltages and frequencies

Cooling Method:: IC411

Insulation System:: Class F

Altitude:: no more than 1000 meters

Protection Class:: IP65

Beide series high efficiency dust explosion-proof Three-Phase Asynchronous Motor is totally enclosed, self-fan cooled high efficiency motor. The products meet the requirements of the GB18613-2020 efficiency of energy efficiency grade 3. The series products introduce Siemens design technology with excellent performance, safe and reliable to use, low vibration, low noise,and meet environmental protection requirements . Its production equipments adopt advanced CNC machine tool equipment, citing Siemens advanced insulation structure design and manufacturing process, use high quality cold rolled silicon steel sheet and high quality bearing with strict quality control .

Beide dust Explosion-proof Motor can be used for food or forage machine, wood machine, flour machine or storage, as well metal,chemicals, synthetic resin, agricultural products and all kinds of combustible dust places such as fiber, fuel and so on . Detailed types of dust refer to "dust characteristics example," but this series motors are not suitable for gas or underground coal mine with combustible dust and coal mine ground device with electrical equipment, also can’t be used in place with explosive dust and spontaneous combustion substances (e .g . phosphorus powder) but can burn without oxygen from the atmosphere .

Beide dust explosion-proof motor's performance fulfill GB 12476 . 1- 2013 "Combustible dust environment for electrical equipment -part 1: General requirements" and GB 12476 .5-2013 "Combustible dust environment for electrical equipment - Part 5: Housing protection type" tD "", suitable for explosive dust environment Zone 21 or zone 22.

1MT0013 Dust explosion-proof motor

Rated output:0.55 ~ 315 kW

Frame size :80 ~ 355

Voltage and Frequency :Support multiple voltage

and frequency

Cooling method:IC411

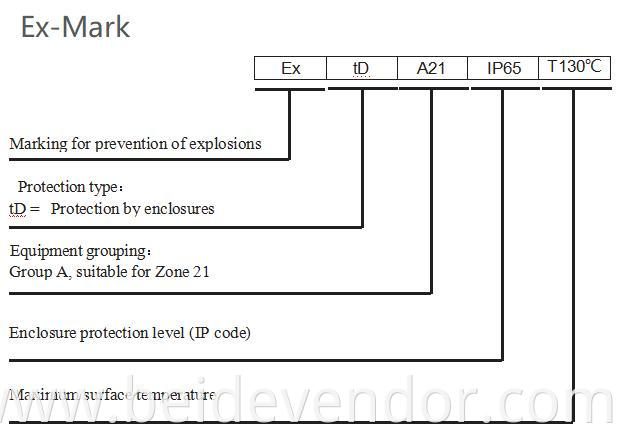

Frame-proof marking:Ex tD A21 IP65 T130℃ Protect degree:IP65

Insulation class : F

Re-greasing device :FS280 and above motor as standard

Ambient temperature :- 15 ℃ ~ +40 ℃

Site altitude above see level:Not exceed 1000m

Company Profile

Siemens Standard Motors Ltd. (SSML)

Siemens Standard Motors Ltd. (SSML) is a Siemens-owned company in China. SSML is located in Yizheng City, Jiangsu Province. The company focuses on developing and producing small and medium low-voltage motors. Currently, SSML mainly produce Siemens brand low voltage AC Motors according to IEC standards, and Beide brand Low Voltage Motors designed according to China local standards.

As one of Siemens main low-voltage motor production facilities worldwide, SSML uses the knowledge and experience of more than 100 years in motor design and manufacturing, owns the advanced manufacture equipment and process, adopts the SIEMENS modern management model , and implements comprehensive quality control according to ISO9001 2015. SSML will continuously serve customers with high quality products and good service.

Explosion-proof Profile

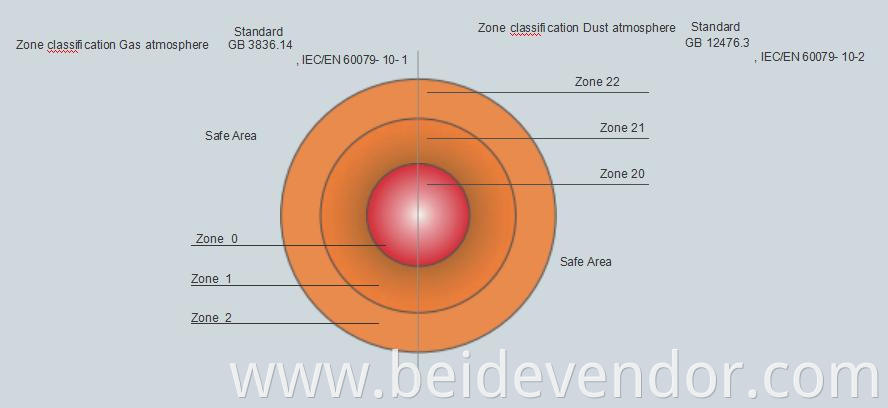

Classification of zones

Areas subject to explosion hazard are divided into zones . Zoning is based on the presence time of explosive substances and probability of explosion . Information and specifications for classification of the zones are laid down in the following standards:

• GB 3836 . 14, IEC/EN 60079- 10- 1 for gas atmospheres

• GB 12476 .3, IEC/EN 60079- 10-2 for dust atmospheres

Furthermore, a distinction is made between various explosion groups as well as temperature classes and these are included in the hazard assessment .

Depending on the particular zone and therefore the associated hazard, operating equipment must comply with defined minimum requirements regarding the type of protection . The different types of protection require corresponding measures to prevent ignition that should be implemented at the motor in order to prevent a surrounding explosive atmosphere from being ignited .

| Zone | Zone definition acc. to GB3836.14 & IEC/EN 60079-10-1 for gas atmospheres GB 12476.3 & IEC/EN 60079-10-2 for dust atmospheres | Assigned types of protection | Category according to 2014/34/EU | Equipment protection level acc. to GB3836.1 & IEC/EN 60079-0 | |

| Gas 1) 2) | Dust 1) 2) | ||||

|

0 |

– | An area in which there is an explosive gas atmosphere constantly, over a long period or frequently. | Low-voltage motors not permitted |

1 |

Ga |

|

1 |

– | An area in which it is expected that an explosive gas atmosphere will occur occasionally during normal operation . | Ex e(GB) or Ex eb(IEC), Ex de, Ex d(GB) or Ex db(IEC) |

2 |

Gb |

|

2 |

– | An area in which it is expected that an explosive gas atmosphere will occur only rarely and then only briefly during normal operation . |

Ex nA(GB) 或 Ex ec(IEC) |

3 |

Gc |

|

– |

20 | An area in which there is an explosive gas atmosphere comprising a dust-air mixture constantly, over a long period or frequently. | Low-voltage motors not permitted |

1 |

Da |

|

– |

21 | An area in which it is expected that an explosive gas atmosphere comprising a dust-air mixture will occur occasionally during normal operation . |

Ex tb |

2 |

Db |

|

– |

22 | An area in which it is expected that an explosive gas atmosphere in the form of a cloud of flammable dust in air will occur only rarely and then only briefly during normal operation . |

Ex tc 3) |

3 |

Dc |

1) Motors of

- Zone 1 can also be used in Zone 2.

- Zone 21 can also be used in Zone 22.

2) Motors which are certified for gas or dust protection must not be used in hybrid mixtures! Hybrid mixtures: when explosive gas and dust atmospheres occur simultaneously.

3) Ex tc motors are not approved for operation in environments containing conductive dust .

Application

The explosion-proof motors are often used in the following industries to prevent explosion hazards that result in serious injury to persons and severe damage to property.Noise levels

The noise levels are measured in accordance with DIN EN ISO 1680

in a anechoic room . It is specified as the A-valued measuring-surface sound pressure level Lpfa in dB (A) . This is the spatial mean value of the sound pressure levels measured on the measuring surface . The measuring surface is a cube 1 m away from the motor surface . The sound power level is also specified as LWA in dB (A) . Please find the noise value in technical data table, the specified values are only valid for totally enclosed fan cooling (cooling method: IC411) motor with no load at 50 Hz with no load, and the tolerance is +3 dB . While motor operating 60 Hz with no load, the values are approximately +4 dB (A) higher.

Vibration

The rotors are dynamically balanced to severity grade A using a half key. Table below contains the effective vibration values for unloaded motors. Vibration grade B can be provided as option.

| Vibration Grade | Frame size (mm) | 56 ≤ FS ≤ 132 | H>132 | ||

| Mounting | Vibration displacement/um | Vibration velocity/(mm/s) | Vibration displacement/um | Vibration velocity/(mm/s) | |

| A | Free suspension | 45 | 2.8 | 45 | 2.8 |

| Rigid mounting | - | - |

| 2.3 | |

| 2.81) | |||||

| B | Free suspension | 18 | 1.1 | 29 | 1.8 |

| Rigid mounting | - | - | - | 1.5 | |

| 1.81) | |||||

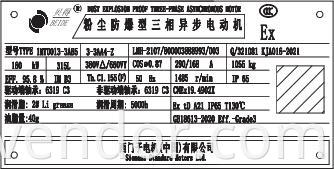

Nameplate

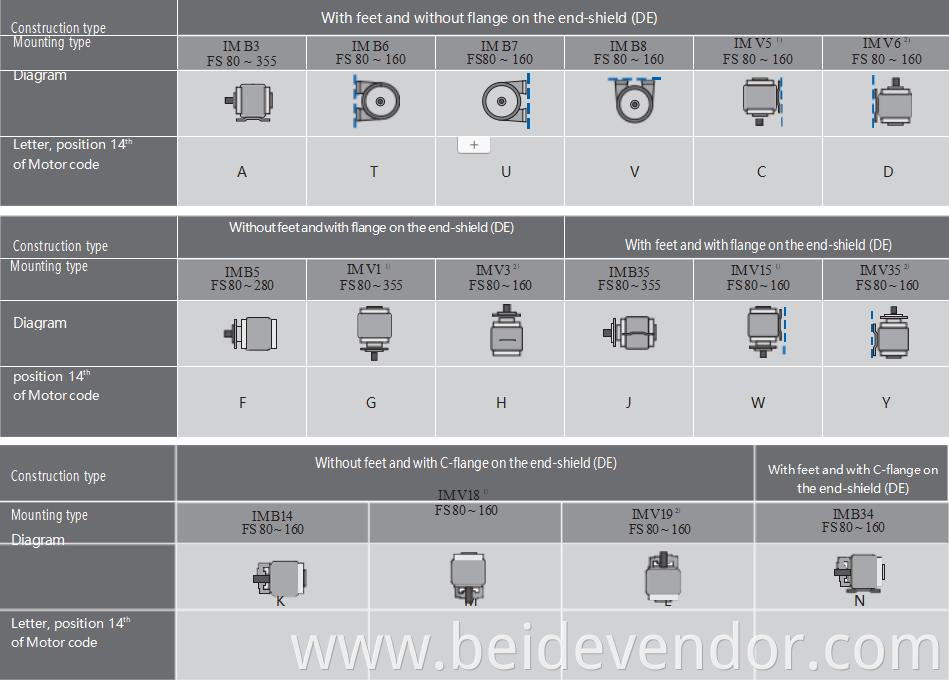

Construction and mounting type

Notes:

1) At outdoor application, the using of protective cover (option code H00) is recommended;

2) At out door application the protection of shaft again jet-water is recommended .

Bearing Assignment

1MT0013 series motors are supplied with the ball bearing as standard . These bearings are either of the sealed or regreasable type .

For FS80 ~ 160, the floating bearings are assembled; for FS180 ~ 355, floating bearing at DE, and fixed bearing at NDE assembled .

The standard bearing can endure a maximum cantilever force, the increased cantilever bearing design (Option code: L22) should be considered .

As standard, FS80 ~ 250 motors are not with regreasing device, but re-greasing device (Option code: L23) can be configured for FS160~250 . FS280~355 motors with regreasable bearing and regreasing device is configured as standard .

| Frame | Pole | Standard design | Increased cantilever-bearing (Option code:L22) | ||||

| DE bearing | NDE bearing (Horizonal mounting) | NDE bearing | DE bearing | NDE bearing(Horizonal mounting) | NDE bearing | ||

| (Vertical mounting) | (Vertical mounting) | ||||||

| 80 | 2,4,6 | 6204 2RZ C3 | 6204 2RZ C3 | 6204 2RZ C3 | — | — | — |

| 90 | 2,4,6 | 6205 2RZ C3 | 6205 2RZ C3 | 6205 2RZ C3 | — | — | — |

| 100 | 2,4,6 | 6206 2RZ C3 | 6206 2RZ C3 | 6206 2RZ C3 | 6306 2RZ C3 | 6206 2RZ C3 | 6206 2RZ C3 |

| 112 | 2,4,6 | 6206 2RZ C3 | 6206 2RZ C3 | 6206 2RZ C3 | 6306 2RZ C3 | 6206 2RZ C3 | 6206 2RZ C3 |

| 132 | 2,4,6,8 | 6208 2RZ C3 | 6208 2RZ C3 | 6208 2RZ C3 | 6308 2RZ C3 | 6208 2RZ C3 | 6208 2RZ C3 |

| 160 | 2,4,6,8 | 6209 2RZ C3 | 6209 2RZ C3 | 6209 2RZ C3 | 6309 2RZ C3 | 6209 2RZ C3 | 6209 2RZ C3 |

| 180 | 2,4,6,8 | 6310 2RZ C3 | 6310 2RZ C3 | 6310 2RZ C3 | NU310 | 6310 2RZ C3 | 6310 2RZ C3 |

| 200 | 2,4,6,8 | 6312 2RZ C3 | 6312 2RZ C3 | 6312 2RZ C3 | NU312 | 6312 2RZ C3 | 6312 2RZ C3 |

| 225 | 2,4,6,8 | 6313 2RZ C3 | 6313 2RZ C3 | 6313 2RZ C3 | NU313 | 6313 2RZ C3 | 6313 2RZ C3 |

| 250 | 2,4,6,8 | 6315 C3 | 6315 C3 | 6315 C3 | NU315 | 6315 C3 | 6315 C3 |

| 280 | 2,4,6,8 | 6317 C3 | 6317 C3 | 6317 C3 | NU317 | 6317 C3 | 6317 C3 |

| 315 | 2 | 6316 C3 | 6316 C3 | 6316 C3 | NU316 | 6316 C3 | 6316 C3 |

| 4,6,8 | 6319 C3 | 6319 C3 | 6319 C3 | NU319 | 6319 C3 | 6319 C3 | |

| 355 | 2 | 6317 C3 | 6317 C3 | 7317 | NU317 | 6317 C3 | O .R . |

| 4,6,8 | 6322 C3 | 6322 C3 | 7322 | NU322 | 6322 C3 | O .R . | |

For permanent lubrication, the bearing grease lifetime is matched to the bearing lifetime . This can, however, only be achieved if the motor is operated in accordance with the catalog specifications .

For motors which can be regreased at defined regreasing intervals, the bearing lifetime can be extended and/or unfavorable factors such as temperature, mounting conditions, speed, bearing size and mechanical load can be compensated .

Grease life (Horizontal installation)

| 座号 Frame size | PolesPoles | Grease lifetime up to CT 40 ºC |

| Grease for permanent lubrication bearing | ||

| 80-250 | 2,4,6,8 | 20000 or 40000 h |

|

| Greasefor regreasable bearing |

|

| 180 ~ 250 | 2 | 4000 h |

| 4,6,8 | 8000 h | |

| 280 ~ 315 | 2 | 3000 h |

| 4,6,8 | 5000 h | |

| 355 | 2 | 3000 h |

| 4,6,8 | 4000 h | |

1)If the coolant temperature is increased by 10 K, the grease lifetime and regreasing interval are halved .

2) 40000 h apply to horizontally installed motors with coupling output without additional axial loads .

When the motor runs outside of normal conditions, the bearing life will be reduced, such as the following conditions .

■ When motor runs beyond the rated speed, the increase of motor vibration will result in the extra radial and axial force on bearing . This will reduce the life of bearing;

■ When the motor vibration increase due to the environment or

other equipment, the bearing also will endure more radial and axial force . This also will reduce the life of bearing;

■ If the coolant temperature is increased by 10 ºC, the grease lifetime and regreasing interval is halved .

Connection boxes technical data

| Frame | No. of main terminal | Main terminal thread | Max. connectable cross-section | Cable diameter (mm) max. ~ min. | Cable entry size | Max. auxiliary terminal |

| 80 | 6 | M4 | 1.5 | 13~18 | M25x1 .5+M16x1 .5 | 12 |

| 90 | ||||||

| 100 | M4 | 4 | 18~25 | M32x1 .5+M32x1 .5 | 12 | |

| 112 | ||||||

| 132 | 6 | |||||

| 160 | M5 | 16 | 22~32 | M40x1 .5+M40x1 .5 | 14 | |

| 180 | ||||||

| 200 | M6 | 25 | 32~38 | M50x1 .5+M50x1 .5 | 14 | |

| 225 | M8 | 35 | ||||

| 250 | M10 | 120 | 37~44 | M63x1 .5+M63x1 .5 | 14 | |

| 280 | ||||||

| 315 | M12 | 150 | 37~44 | M64x2 + M64x2 | 18 | |

| 355 | M16 | 240 | 42~54 | M72x2 + M72x2 | 18 |

| Cable entry size | Allowed outer cable diameter range (mm) | Allowed core number range of cable | Nominal section area of connection (conductor)(mm2) |

| M16 x 1.5 | 8-11 | 2-7 | 1 mm2 |

| M20 x 1.5 | 11- 14 .3 | 8-10 | 1 mm2 |

| M27 x 2 | 13-20 .2 | 12-27 | 1 mm2 |

Note:

1. Power cables are recommended to use YJV (GB/17206) crosslinked polyethylene insulation and PVC sheath 3+1 copper core cable .

2. The control cable of weak current signal is recommended to use KVV (GB/T9330) polyvinyl chloride insulated sheath copper core section 1 mm2 multi-core control cable .

3. The heating line is a strong signal control, please use the KVV copper core section 2 x 1mm 2 control cable to enter the line alone .

4. If the cable diameter is not in the range of explosion protection, the electric motor will lose the explosion-proof property.

5. If you need to use an armored gland, please make a special inquiry.

Electrical design

Rated Output

| Voltage deviation | ±5 % | ± 10 % |

| Frequency deviation | ±2 % | +3 % / -5 % |

| According to the standard, longer operation is not recommended for Category B . | ||

Tolerance for electrical data

■ Efficiency ηat

Prated ≤ 150 kW: - 0.15 x (1 – η)

Prated > 150 kW: - 0.10 x (1 – η)

|

■

■ ■ ■ ■ ■ | With η being a decimal number Power factor :(1 – cos φ) / 6 Minimum absolute value:0.02 Maximum absolute value:0.07 Slip ±20 % (for motors < 1 kW ±30 % is admissible) Locked-rotor current +20 % Locked-rotor torque - 15 % to +25 % Breakdown torque - 10 % Moment of inertia ± 10 % |

Certificates

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.