BEIDE 4KW IE4 Cast Iron Three-phase Asynchronous Motor

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean |

| Port: | shanghai |

Select Language

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Ocean |

| Port: | shanghai |

Brand: Beide

Application:: chemical and petrochemical industries, etc.

Rated Power:: 0.55 ~ 90 kW

Frame Size: 80 ~ 280

Voltage And Frequency:: Supports multiple voltages and frequencies

Cooling Method:: IC411

Insulation System:: Class F

Altitude:: no more than 1000 meters

Protection Class:: IP65

1TL0004 series of motors is the newly designed high efficiency low voltage Three Phase Asynchronous Motor, is designed for continuous duty operation(S1). 1TL0004 series of motors owns the features of high efficiency, novel structure, beautiful appearance, low noise, small vibration, high degree of insulation, etc, also can be used in the fields of fans, pump, compressors and textile machine.

1TL0004 Cast Iron series Low-voltage Three-Phase Asynchronous Motor

Rated output:1.5 ~ 315 kW Frame size:100 ~ 355

Voltage and Frequency:support multiple voltage andfrequency

Cooling method:IC411

Oiling device:FS180~355 motor as standard Degree of protection:IP55

Degree of insulation:F

Coolant temperature:-15 ~ 40 ºC

Site altitude above see level:not exceed 1000 m

Company Profile

Siemens Standard Motors Ltd. (SSML)

Siemens Standard Motors Ltd. (SSML) is a Siemens-owned company in China. SSML is located in Yizheng City, Jiangsu Province. The company focuses on developing and producing small and medium low-voltage motors. Currently, SSML mainly produce Siemens brand low voltage AC Motors according to IEC standards, and Beide brand Low Voltage Motors designed according to China local standards.

As one of Siemens main low-voltage motor production facilities worldwide, SSML uses the knowledge and experience of more than 100 years in motor design and manufacturing, owns the advanced manufacture equipment and process, adopts the SIEMENS modern management model , and implements comprehensive quality control according to ISO9001 2015. SSML will continuously serve customers with high quality products and good service.

Reference standards

| Title | IEC standard | Chinese standard |

| Rotating electrical machines – Part 1: Rating and performance | IEC 60034-1

| GB/T 755

|

| Rotating electrical machines – Part 2-1: Standard methods for determining losses and efficiency from tests (excluding machines for traction vehicles) | IEC 60034-2

| GB/T 1032

|

| Rotating electrical machines – Part 5: Degrees of protection provided by the integral design of rotating electrical machines (IP code) - Classification | IEC 60034-5

| GB/T 4942.1

|

| Rotating electrical machines – Part 6: Methods of cooling (IC Code) | IEC 60034-6

| GB/T 1993

|

| Rotating electrical machines – Part 7: Classification of types of construction, mounting arrangements and terminal box position (IM Code) | IEC 60034-7

| GB/T 997

|

| Rotating electrical machines – Part 8: Terminal markings and direction of rotation | IEC 60034-8

| GB/T 1971

|

| Rotating electrical machines – Part 9: Noise limits | IEC 60034-9

| GB 10069.3

|

| Rotating electrical machines – Part 14: Mechanical vibration of certain machines with shaft heights 56 mm and higher – Measurement, evaluation and limits of vibration severity | IEC 60034-14

| GB 10068

|

| Rotating electrical machines – Part 1: Frame numbers 56 to 400 and flange numbers 55 to 1080 | IEC 60072-1

| GB/T 4772.1

|

| Safety requirements of small and medium size rotating electrical machines |

| GB 14711

|

| Electrical insulation – Thermal evaluation and designation | IEC 60085

| GB/T 11021

|

| Classification of environmental conditions Part 2-1: Environmental conditions appearing in nature – Temperature and humidity | IEC 60721-2-1

| GB/T 4797.1

|

| Standard voltages | IEC 60038

| GB/T 156

|

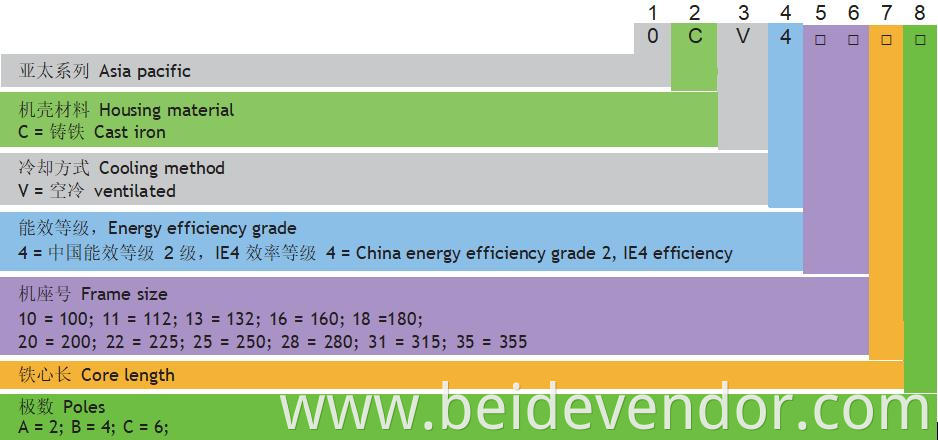

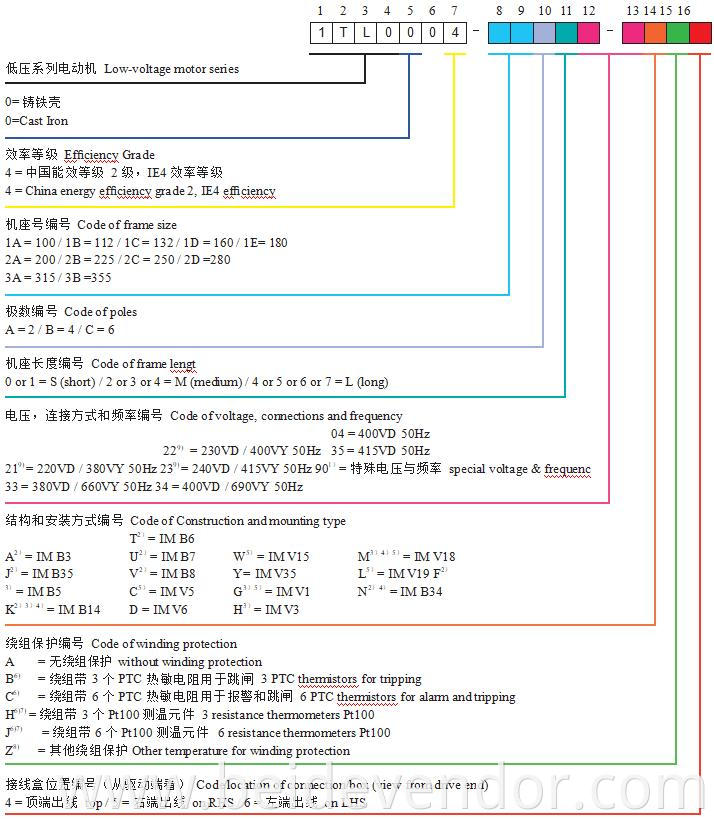

Motor type

1) Motor type can be used for energy efficiency filing.

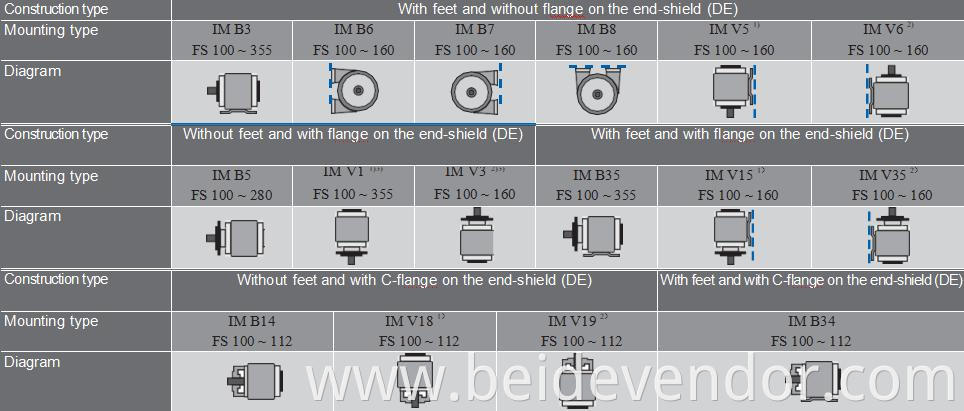

Construction and mounting type

1) At outdoor application, the using of protective cover (Option code H00) is recommended

2) At out door application the protection of shaft again jet-water is recommended

3) Full circle flange as standard configuration in this type mounting.

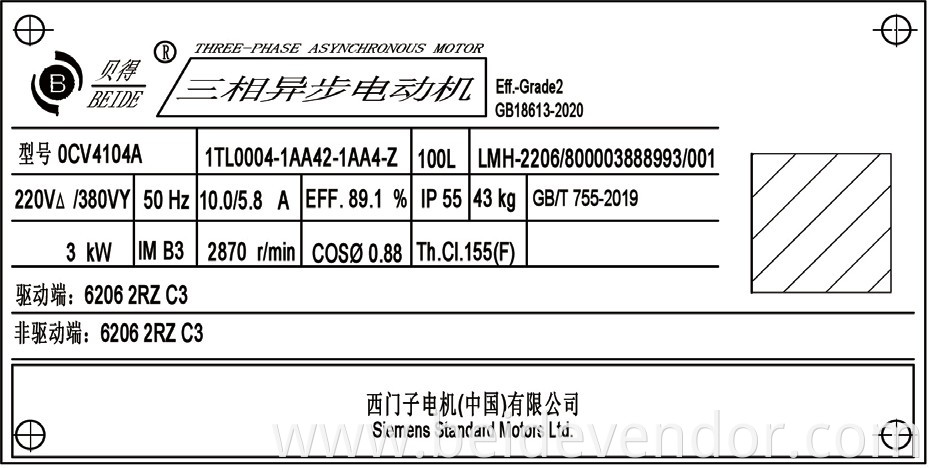

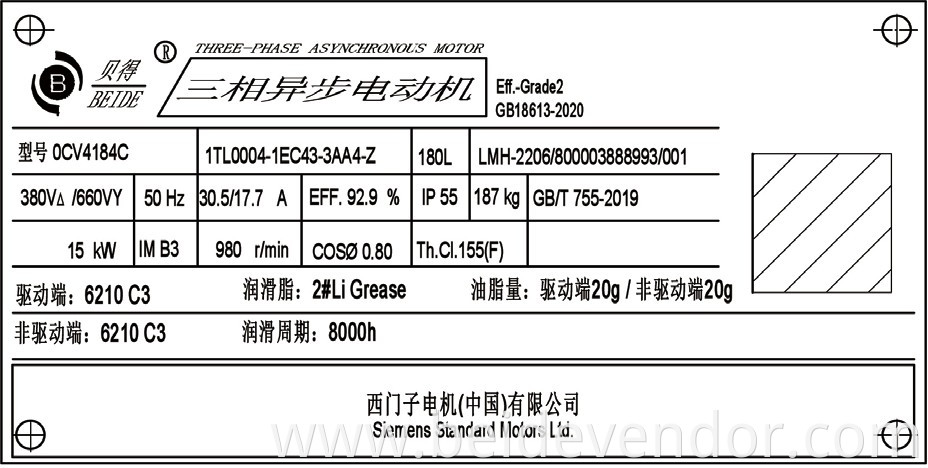

Nameplate

Example of motor with sealed bearing nameplate Example of motor with regreasable bearing nameplate

Bearing system

1TL0004 series motors are supplied with the ball bearing as standard. These bearings are either of the sealed or regreasable type.

For FS100 ~ 160, the floating bearings are assembled; for FS180 ~ 355, floating bearing at DE, and fixed bearing at NDE assembled.

The standard bearing can endure a maximum cantilever force, the increased cantilever bearing design (Option code: L22) should be considered.

Bearing Assignment

|

Frame size

| Pole

| Standard design | Increased cantilever-bearing (Option code:L22) | ||||

| DE bearing |

NDE bearing (Horizonal mounting) |

NDE bearing (Vertical mounting) | DE bearing | NDE bearing (Horizonal mounting) |

NDE bearing (Vertical mounting) | ||

| 100 | 2,4,6 | 6206 2RZ C3 | 6206 2RZ C3 | 6206 2RZ C3 | 6306 2RZ C3 | 6206 2RZ C3 | 6206 2RZ C3 |

| 112 | 2,4,6 | 6206 2RZ C3 | 6206 2RZ C3 | 6206 2RZ C3 | 6306 2RZ C3 | 6206 2RZ C3 | 6206 2RZ C3 |

| 132 | 2,4,6 | 6208 2RZ C3 | 6208 2RZ C3 | 6208 2RZ C3 | 6308 2RZ C3 | 6208 2RZ C3 | 6208 2RZ C3 |

| 160 | 2,4,6 | 6209 2RZ C3 | 6209 2RZ C3 | 6209 2RZ C3 | 6309 2RZ C3 | 6209 2RZ C3 | 6209 2RZ C3 |

| 180 | 2,4,6 | 6210 C3 | 6210 C3 | 6210 C3 | NU210 | 6210 C3 | 6210 C3 |

| 200 | 2,4,6 | 6312 C3/6212 C3* | 6212 C3 | 6212 C3 | NU312/NU212* | 6212 C3 | 6212 C3 |

| 225 | 2,4,6 | 6213 C3 | 6213 C3 | 6213 C3 | NU213 | 6213 C3 | 6213 C3 |

| 250 | 2,4,6 | 6215 C3 | 6215 C3 | 6215 C3 | NU215 | 6215 C3 | 6215 C3 |

| 280 | 2,4,6 | 6317 C3 | 6217 C3 | 6217 C3 | NU317 | 6217 C3 | 6217 C3 |

|

315 | 2(S/M) | 6316 C3 | 6316 C3 | 6316 C3 | NU316 | 6316 C3 | 6316 C3 |

| 2(L) | 6316 C4 | 6316 C4 | 7316 | NU316 | 6316 C4 | 6316 C4 | |

| 4(S/M), 6 | 6319 C3 | 6319 C3 | 6319 C3 | NU319 | 6319 C3 | 6319 C3 | |

| 4(L) | 6319 C4 | 6319 C4 | 7319 | NU319 | 6319 C4 | 6319 C4 | |

| 355 | 2 | 6317 C3 | 6317 C3 | 7317 | NU317 | 6317 C3 | 6317 C3 |

| 4 | 6322 C3 | 6322 C3 | 7322 | NU322 | 6322 C3 | O.R | |

Grease life and re-greasing interval

For permanent lubrication, the bearing grease lifetime is matched to the bearing lifetime. This can, however, only be achieved if the motor is operated in accordance with the catalog specifications.

For motors which can be regreased at defined regreasing intervals, the bearing lifetime can be extended and/or unfavorable factors such as temperature, mounting conditions, speed, bearing size and mechanical load can be compensated.

Grease life (Horizonal installation)

| Frame size | Poles | Grease lifetime up to CT 40 ºC |

| Grease for permanent lubrication bearing | ||

| 100-160 | 2,4,6 | 20000or40000h |

| Grease for regreasable bearing | ||

| 180-250 | 2 | 4000h |

| 4,6 | 8000h | |

| 280 | 2 | 3000h |

| 4,6 | 5000h | |

| 315 | 2 | 3000h |

| 4,6 | 4000h | |

| 355 | 2 | 3000h |

| 4,6 | 4000h | |

Connection boxes technical data

| Frame size | Contact screw thread | Outer cable diameter (sealing range)(mm) | Cable entry size |

| 100 | M4 | 10 ~ 14 | M24 x 1.5 |

| 112 | M5 | 13 ~ 18 | M27 x 2 + M27 x 2 |

| 132 | M4 | 18 ~ 25 | M32 x 1.5 + M32 x 1.5 |

| 160 - 180 | M5 | 22 ~ 32 | M40 x 1.5 + M40 x 1.5 |

| 200 | M8 | 22 ~ 32 | M48 x 2 + M48 x 2 |

| M6* | 32 ~ 38* | M50 x 1.5 + M50 x 1.5* | |

| 225 | M8 | 32 ~ 38 | M50 x 1.5 + M50 x 1.5 |

| 250 | M10 | 37 ~ 44 | M63 x 1.5 + M63 x 1.5 |

| 280 | M10 | 37 ~ 44 | M64 x 2 + M64 x 2 |

| 315 2P (S/M) 4P (S/M) 6P | M12 | 37 ~ 44 | M64 x 2 + M64 x 2 |

| 315 2P (L) 4P (L) | M12 | 44 ~ 57 | M72 x 2 + M72 x 2 |

| 355 | M16 | 38 ~ 47 | M72 x 2 + M72 x 2 |

Vibration

1TL0004 rotors are dynamically balanced to severity grade A using a half key.

Table below contains the effective vibration values for unloaded motors

| Vibration Grade | Frame size (mm) | 56 ≤ FS ≤ 132 | H>132 | ||

| Mounting | Vibration displacement/um | Vibration velocity/(mm/s) | Vibration displacement/um | Vibration velocity/(mm/s) | |

|

A | Free suspension | 45 | 2.8 | 45 | 2.8 |

| Rigid mounting | - | - | 37 | 2.3 | |

| 2.81) | |||||

|

B | Free suspension | 18 | 1.1 | 29 | 1.8 |

| Rigid mounting | - | - | 24 | 1.5 | |

| 1.81) | |||||

Note:

1) The level are vibration velocity limit when the twice line frequency vibration level is dominant defined by GB/T 10068-2020, for 2p motors that frame size bigger than 132mm.

Anti-condensation heater

Motors whose windings are at risk of condensation due to the climatic conditions, e.g. inactive motors in humid atmospheres or motors that are subjected to widely fluctuating temperatures can be equipped with anti-condensation heaters (Option code: Q04). Anti-condensation heaters must be switched off during operation. When motor shut down, the heaters must be switched on.

Electrical data of Anti-condensation heater

| Frame size | Power(W) | Voltage(V) |

| 100 ~ 112 | 30 | 220 |

| 132 ~ 160 | 40 | 220 |

| 180 ~ 200 | 50 | 220 |

| 225 ~ 280 | 60 | 220 |

| 315 | 80/1001) | 220 |

| 355 | 100 | 220 |

Electrical design

Rated Output

1TL0004 motors rated output powers means that the motor runs under continuous duty S1 (IEC 60034 - 1) operation when operated at ambient temperature from -15 ºC to 40 ºC and at altitudes of up to 1000 m over sea.

Voltage and Frequency

IEC 60034-1 differentiates between Category A (combination of voltage deviation ±5 % and frequency deviation ±2

%) and Category B (combination of voltage deviation

±10 % and frequency deviation +3 % / -5 %) for voltage and frequency fluctuations. The motors can supply their rated torque in both Category A and B. In Category A, the temperature rise is approximately 10 K higher than during normal operation.

| Standard 60034 - 1 | Category A | Category B |

| Voltage deviation | ±5 % | ±10 % |

| Frequency deviation | ±2 % | +3 % / -5 % |

| According to the standard, longer operation is not recommended for Category B. | ||

1TL0004 motors are suitable for pumps, fans, compressors, texitle machine and mechanical machine applications where variable or constant speed is required.

The standard insulation of the 1TL0004 motors is designed such that operation is possible on the converter at mains voltage up to 460 V.

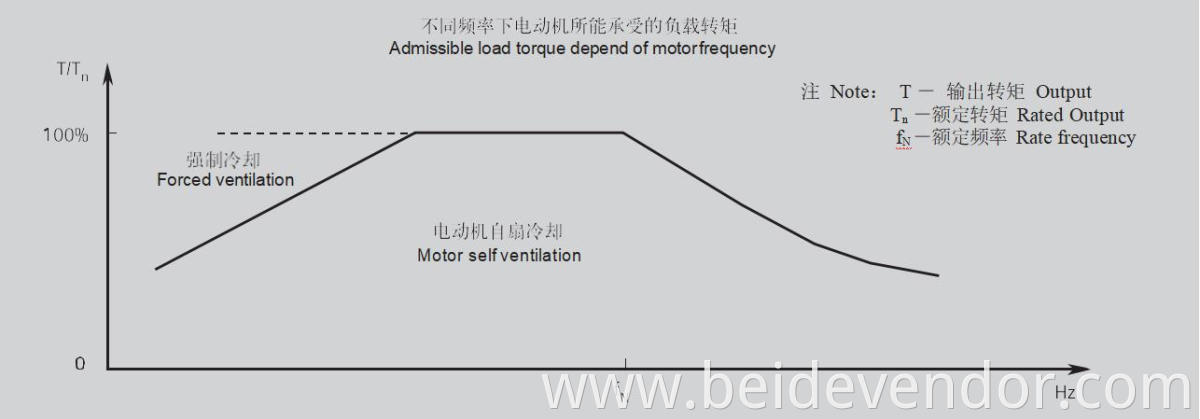

1TL0004 motors are capable for converter-fed operation with certain characteristics load, of which the load torque characteristics is referred in the following diagram:

At rated output with converter fed operation, the motors will be used in temperature class 155 (F). To prevent damage as a result of bearing currents, insulated bearings are recommended to be assembled for frame size 250 and above. Please inquire Siemens about the detailed information of insulated bearing.

By usage with admissible torque and below, the motor can be operated with self cooling; by usage over the admissible torque line, the motor with forced ventilation is needed.

At operating speeds above rated speed the noise and vibration levels increase and the bearing life time reduce. Attention should be paid to the re-greasing intervals and the grease service life.

The allowed maximum safe operating speed of 1TL0004 motors shows the diagram

| Frame size | 2 pole | 4 pole | 6 pole | |||

| Max.rpm | fmax | Max.rpm | fmax | Max.rpm | fmax | |

| 100 | 5200 | 87 | 3600 | 120 | 2400 | 120 |

| 112 | 5200 | 87 | 3600 | 120 | 2400 | 120 |

| 132 | 4500 | 75 | 2700 | 90 | 2400 | 120 |

| 160 | 4500 | 75 | 2700 | 90 | 2400 | 120 |

| 180 | 4500 | 75 | 2700 | 90 | 2400 | 120 |

| 200 | 4500 | 75 | 2300 | 77 | 1800 | 90 |

| 225 | 3600 | 60 | 2300 | 77 | 1800 | 90 |

| 250 | 3600 | 60 | 2300 | 77 | 1800 | 90 |

| 280 | 3600 | 60 | 2300 | 77 | 1800 | 90 |

| 315 | 3600 | 60 | 2300 | 77 | 1800 | 90 |

| 355 | 3600 | 60 | 2300 | 77 | 1800 | 90 |

Technical data for separately fan

Technical data for separately fan

| Motor frame size | rated voltage (V) | Rated frequency(Hz) | Rated output(W) | Current (A) | ΔL |

| 100 |

220D/380Y | 50 | 52 | 0.21/0.12 | 65 |

| 112 | 50 | 52 | 0.21/0.12 | 75 | |

| 132 | 50 | 45 | 0.35/0.2 | 75 | |

| 160 | 50 | 45 | 0.35/0.2 | 55 | |

| 180 | 50 | 120 | 1.04/0.6 | 65 | |

| 200 | 50 | 120 | 1.04/0.6 | 60/65* | |

| 225 | 50 | 120 | 1.04/0.6 | 60 | |

| 250 | 50 | 230 | 1.73/1.0 | 80 | |

| 280 | 50 | 230 | 1.73/1.0 | 105 | |

| 315 2P (S/M) 4P (S/M) 6P | 50 | 370 | 1.91/1.1 | 95 | |

| 315 2P (L) 4P (L) | 50 | 1100 | 4.33/2.5 | 180 | |

| 355 | 50 | 550 | 2.18/1.26 | 100 |

Order No.

Foot note:

1) Order other voltages with voltage code 90 and the corresponding Option code (see under "Option") .

2) The type of construction is stamped on the rating plate. When ordering with condensation drainage holes (order code H03), it is absolutely necessary to specify the type of construction for the exact position of the condensation drainage holes during manufacture.

3) For motor with IM B5, IM V1, IM V3, IM B14, IM V18 and IM V19 construction and mounting type, the 16th digit of motor order No. must be "4";

4) Only for FS100 ~ 112.

5) Without canopy, for protective cover with canopy needed Option code H00.

6) Choose this option, the connection box will be changed to cast iron.

7) Only applicable for frame size 100-355.

8) Please specially consult with Siemens.

9) Not applicable for FS315 ~ 355 motors.

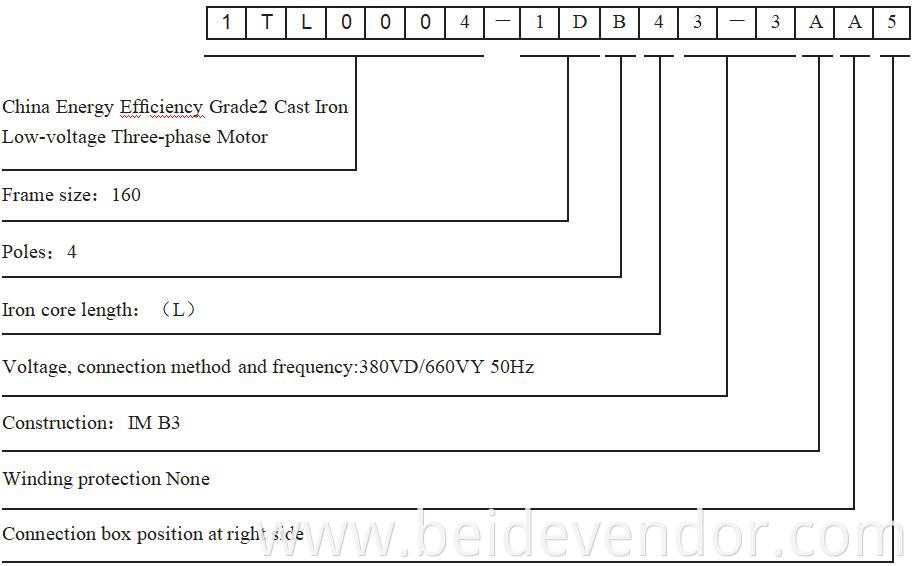

Order No. example:

China Energy Efficiency Grade2 low voltage three phase asynchronous motor

4-pole, 15 kW, IM B3, 380VD/660VY 50 Hz, IP55,

connection box at right side and cable entry at bottom (view from DE)

Motor order code: 1TL0004-1DB43-3AA5

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.